"CIRAS has been huge for us. I actually sent two of my engineers down there today to work with them again."

- Eric Mathias, Pengo Corporation, Laurens

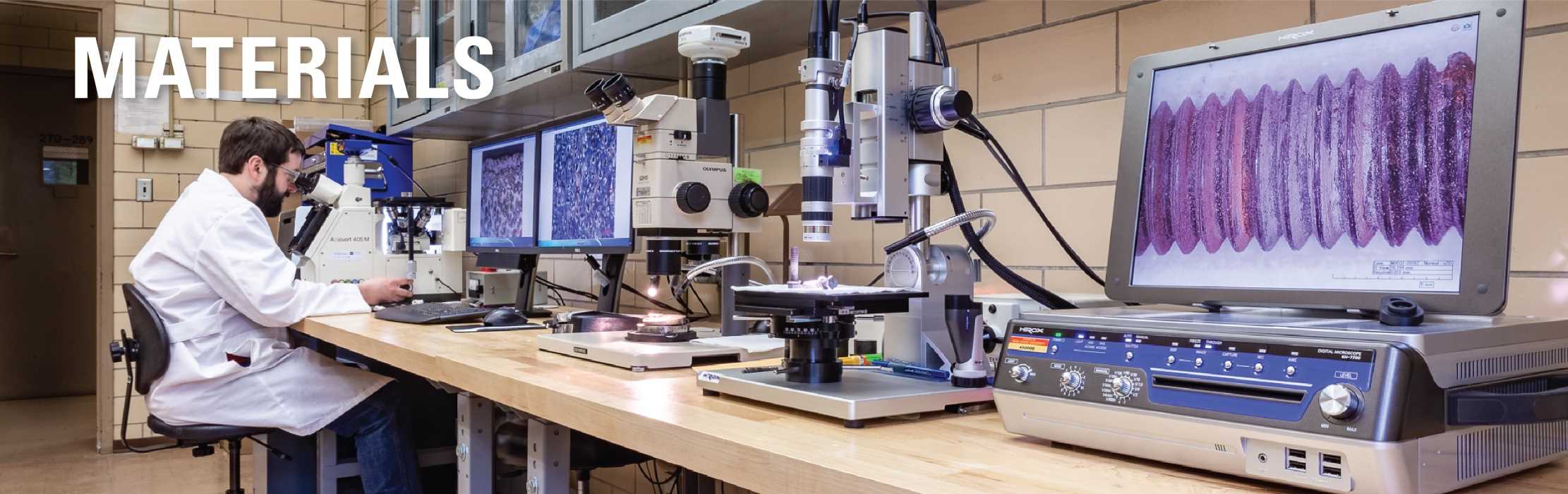

Materials Testing Resources at ISU

At times, Iowa companies may find themselves with questions about the materials used in their products. Why are they failing or under-performing? Did our supplier send us what we ordered? Will this substance be able to handle the demands of our particular product design?

CIRAS can help find answers. Metallurgists with the CIRAS Technology Assistance Program (TAP) have spent years working with Iowa businesses to improve products and processes.

CIRAS can help with:

- Analysis of why a product failed or an explanation for under-performing parts

- Guidance in selecting the best material for a particular job

- Clarity on material specifications

- Confirmation of what a supplier has provided

- Education on corrosion issues

CIRAS materials engineering experts have a variety of capabilities to solve materials problems. Our toolbox includes:

- Compositional analysis

- Hardness and mechanical properties testing

- A full metallurgical sample prep lab

- Optical, digital, and electron microscopy labs that can be used for metallography, fractography, and microanalysis

To learn more about how CIRAS materials engineering specialists can help your company, contact Bruce Janvrin.

CIRAS provides several related services, including: